Reinventing the Wheel

- brian

- Oct 16, 2012

- 6 min read

A tale of adventure and self-discovery at Barobo Inc.

By Brian Broderick

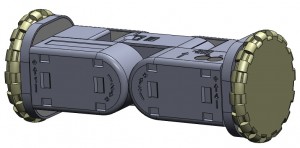

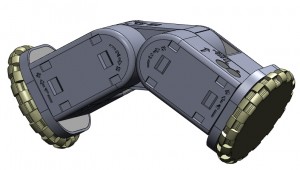

“Brian, I need you to design a new wheel for the Mobot.” Graham, founder and head engineer of Barobo, went on to explain that the new wheel model would have to interface well with both carpeted and smooth surfaces, in addition to being robust enough to survive the frequent drops and bumps that occur in the classroom environment. These were my first real design problems of my first real project at my first real job and the intensity of the moment was palpable. I knew nothing about wheels, even less about designing them, but I also knew great engineering begins with fearless grit. So, with nothing but an internet full of resources and a freshly installed copy of SolidWorks, I quelled my inhibitions and embarked on the journey of a lifetime.

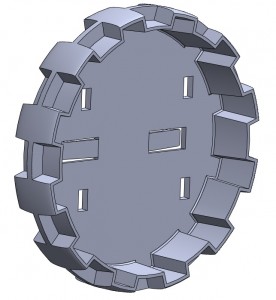

Engineers and laymen alike know the intimidation of beginning a new project. Not knowing where to begin and in a slight panic, I racked my memory for any experience I had with wheels. Inspiration came, surprisingly enough, from my childhood: the LEGO tire, a regular component of my juvenile creations. Both functional and simple, the lego tire has tread sections alternating on either side providing good traction while maintaining a constant radius for smooth rolling. It was as good a start as any, so the question became: how could I redesign the features of this timeless classic to work with the mobot? The most prudent modification seemed to be a rounded rolling surface to maintain good contact even when the Mobot wasn’t fully extended and, after some rough sketches and a design check with Graham, I began to CAD model my first part.

The geometry of the wheel was fairly simple, little more than a flat disk with a few cuts and extrusions. But, as I progressed in the modeling process, I began to feel something primal stir within me. Seeing the growingly complex features appear beneath my mouse cursor, the sensation that Michelangelo must have had while carving David became very clear to me. This was the manifestation of thought in reality, a chasmic leap from the neurons of my mind to the pixels of my computer screen. Unlike Michelangelo though, I was unbound by the the limits of stone and chizzle. All I could conceive was possible and as I delved deeper into the design, the boundary between imagination and reality became as nebulous as a thin fog. In short, I was Ellen Page in Inception, though much less attractive.

Once I had tasted the sweet nectar of design, I knew I could never return to the tranquil docility of my earlier life and design became the fixation of my every waking minute. Fortunately, though, Barobo was an oasis of design possibilities and the open ended wheel project gave me the opportunity to satiate my creative cravings. I began to create models of growing complexity and absurdity, monstrosities better suited to science fiction films that children’s robots. As I felt the fingers of insanity clawing at my mind, Graham descended to my rescue with a revelation that wrenched me from my mania and refocused me on the mission like a starving cheetah on a limping gazelle. The original design derived from the Lego tire was adequate, he thought, but now what was needed was to convert it to a two-half, shell design that could snap together for simple and rapid assembly and save on material costs by allowing dead space in the interior. He went on to informed me, in a tone the betrayed nothing of the immense gravity of his words, that the part I was designing might ultimately be plastic injection molded.

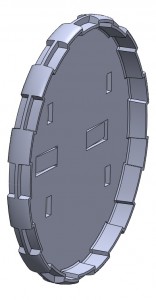

I spent the next few days frantically researching snap connection joints. With our circular geometry, an annular snap joint like those found on over-the-counter tylenol bottles seemed ideal. It would allow for quick, secure, and irreversible assembly and would integrate well into the interior space of the model. Snap connectors, however, generally require overhang. This complicated the project somewhat because plastic molds that can form overhang are typically very expensive. My only chance at avoiding this added expense would be to design my part so that it could be molded using what’s called a “bump-off”. This is where the freshly molded plastic stretches around overhanging features of the mold when being ejected from the mold, allowing an overhang on the part to be formed without expensive extra techniques. After designing a prototype of the part and submitting it to our plastic injection service I found that while one half of the design would, indeed, be compatible with the bump-off process, the other half that required overhang on the exterior rim would be impossible without using the expensive methods.

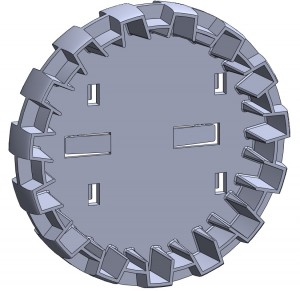

After explaining the situation to graham and showing him some alternative snap connector options we decided that a two-sided design might be more of a complication than simplification and discussion began on possible single part designs. After modeling a few potentials, we became enamored of a treaded wheel with a central rib to allow for an even rolling surface. The design was very mold-friendly, requiring no overhang and having space for generous draft angles for easy removal from the mold. Initially, I was eager to include a series of exotic-looking reinforcement ribs to brace the tread of the tire. However, after I submitted the model for evaluation by the molding service I found that forming the ribs in a mold would add a great deal of expense and, because they were more cosmetic than functionally necessary, we decided to have them removed to reduce expense. Even after the ribs were removed, the treaded wheel was still very expensive to mold, so in a further attempt, I reduced the width of the wheel. While the width reduction did reduce the cost somewhat, it still wasn’t enough to drop it blow our price goal.

After discussing the economics of the situation, Graham and I decided that that a plastic injection wheel like the one I had designed probably wouldn’t be viable for production until later in the company’s development when higher sales could offset the steep entry expense of creating the mold. My part wasn’t shelved completely, though, as there was still the potential for it to be produced and sold on a limited scale through plastic printing. The model in its current state, while very good for plastic injection molding, wasn’t well suited to plastic printing as it would require a large amount of support material to build the center rolling ring as the wheel was printed layer by layer laying on its side. So, the next task became altering the model so that it could be efficiently plastic printed. The modifications involved reducing the wall thickness and removing the unneeded surface drafts to save on material as well as shifting the rolling ring to the interior side of the wheel to reduce the support material requirements during printing. The new wheel looked significantly different from the original, plastic-injection model and ultimately, when Graham was deciding which to print for testing he decided that he liked the original with the center rolling ring better than the one modified for plastic printing despite the original’s additional printing cost.

It felt fantastic to hold my own part, especially given the long road that had led to it’s creation. The biggest lesson I learned was to be flexible in my thinking. At several stages of the design I ultimately was inefficient in my time use because I was focused too much on a particular kind of solution to the given problem rather than thinking outside of the box for a better suited solution. I probably should have identified more quickly the inescapable expense of an annular snap connector joint and found an alternative rather than spending excess time trying to figure out how to tweak the geometry to make it affordable. Additionally, I learned the importance of keeping the limits of the manufacturing process in mild while designing. I could have saved a lot of time in my attempts at price saving modifications on the injection molded model if I had remembered that deep thin features and small radius corners add a lot of expense to molds. All these lessons will be invaluable moving forward, though, and in the end I’m confident the speed and efficiency they’ll facilitate in my later work will be well worth the mistakes required to learn them.

Comments